A good proven car service has problems installing auto parts under the Siberian suspension brand. We are responsible for quality, as evidenced by both positive reviews about our products and regular customers in all 85 regions of Russia, in the countries of near and far abroad. However, small details in the installation should be considered in order to avoid any complications.

With the following information, you will be protected from “unexpected” problems.

1. The most common problem is that a car owner purchased spare parts by the name of the brand and model of the car without taking into account the VIN or body number. In 80% of cases, spare parts will not fit.

2. Another variant of the same problem – spare parts were purchased in accordance with the VIN or body number, but it turned out that a specific lever on the car was replaced, and the owner did not take into account its OEM! In such cases, spare parts will also not fit. Please note that OEM details are indicated on the product card on our website.

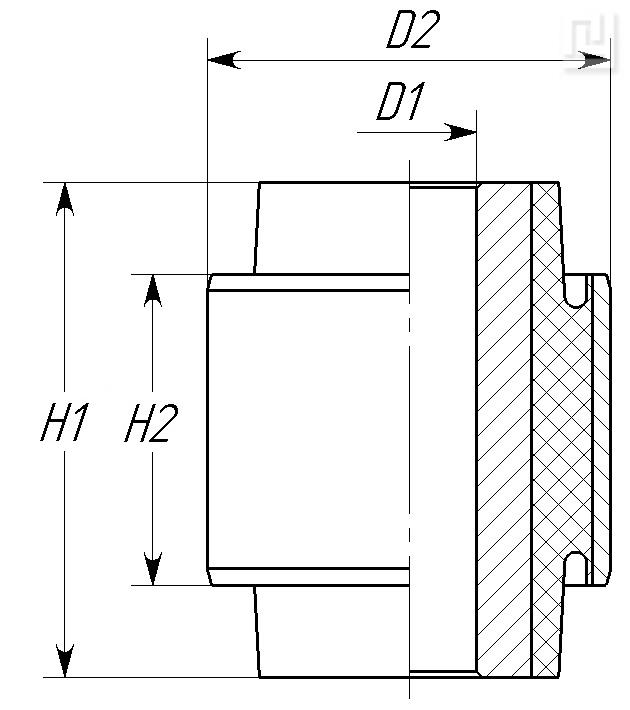

3. Before installation, the main dimensions were not measured, for example, sleeve length, seat dimensions. The result is that the car is disassembled, the part cannot be installed. Please note that if you are choosing a part by size, it is very important to take into account all the required dimensions. Otherwise, sizing will be incorrect. For example, for silent blocks you need to measure 4 parameters, not 3, as some people do!

4. Installation of silent blocks without removing the levers. Almost no one succeeds in doing it well. Hence the problems, since it is more difficult to achieve the alignment of the silent block and the seat of the lever.

5. Pressing in a vice. Possible problem: damage to a seat or a part. Solution: in the absence of extensive experience in working with a vice, it is better to press in on special equipment. The following video shows how the silentblock is pressed in on pressing equipment using cones.

6. Incorrect selection of auxiliary press fittings: mandrels, thrust washers, spacers. In this case, it will be difficult to press in the part exactly without distortion or deformation. As a result, you can damage not only the silent block, but also the assembly into which it is pressed. This is especially true for levers with a U-shaped profile. Be careful when selecting!

7. When pressing in silent blocks without an external metal sleeve, the distribution of elastic material in the seat must be properly taken into account, and the absence of burrs at the edges of the seat must be checked.

8. Ignorance of the “subtleties” of the installation – for example, how much grease to put; how to accurately install the silent block so that pressure is evenly distributed during pressing, etc. Some people lack the thoroughness of stripping when preparing the unit for installation.

As you can see, the entire list refers to the problems of the lack of sufficient skills of the auto technician who took up the installation. This results in either incorrect installation or significant time costs. From here comes the disappointment in the purchased auto parts. The car owner goes to buy others, hoping that “they will be better.” But if you don’t change the approach to installation, other parts will again disappoint.

After reading this information, you can better decide what to do: carry out repairs yourself, taking into account our recommendations, or entrust the car to a qualified specialist. For more information on installation, see our blog:

If you have any more questions about the installation, you can always ask us for advice in the chat on the website and by e-mail [email protected]