We offer an effective and, perhaps, the best replacement for bushings with a vertical axle position in the suspension unit, operating in “swinging” conditions.

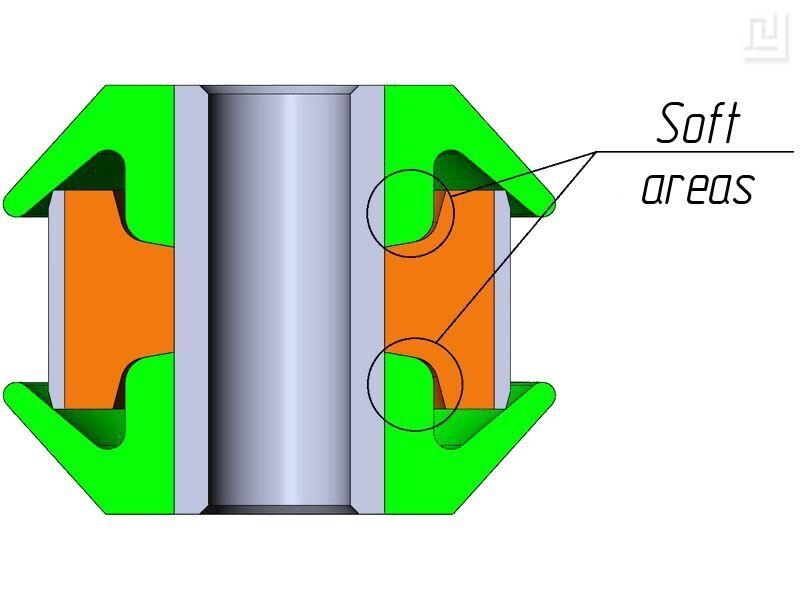

Initially, such bushings have a more complex configuration. They have additional zones of softness, designed for unhindered swinging of the bushing relative to the inner metal sleeve and to reduce deformation of the rubber part.

When using original products of this type, the following problems often arise:

- Separation of the inner metal sleeve.

- Breaking and deformation of the entry point of the inner sleeve.

- Dust and dirt getting into the hole and, as a result, creaking and accelerated wear of the entire silent block.

The solution has been found – composite polyurethane bushings!

As a solution to these problems, the company “Polyurethan” has released bushings of improved design – composite bushings.

Outstanding design differences of the composite bushing

The composite bushing consists of 4 separate parts: a central part (outer metal sleeve plus polymer layer), an inner metal sleeve and 2 dust boots. The ready-to-sell product is composed from the listed components – hence the name “composite“. Such a solution is possible due to the incredible resistance of polyurethane to abrasion and friction at the points of contact between polyurethane-metal and polyurethane-polyurethane. Rubber is unsuitable for this design.

Solving the problem of separation of the metal sleeve

The problem of separation of the metal sleeve is solved in such a way that in these bushings the inner metal sleeve is not glued to the polymer layer, but is pressed in (for more details, see the article about bushings with a pressed-in inner sleeve). Thus, the separation of polyurethane from the metal is impossible, since there is initially no connection between them.

Unobstructed swing of the composite vertical bushing

Unlike simply “pressed” bushings, “compound” ones are designed taking into account the softness zones, which are so important in the construction of vertical silent blocks. That is, the “composite” silent block of our production also has softness zones comparable to those of the original part and performing the same function, only they are made differently, using the differences in properties of polyurethane and rubber.

Solving the problem of dust and dirt

The problem of dust and dirt ingress was solved by the additional installation of two anthers that protect our silent block. The anthers also prevent vertical displacement of the silent block.

To increase the service life of the silent block and prevent squeaks, it is recommended to fill the contact areas of the metal with polyurethane with grease. A more detailed guide for installing such silent blocks can be found in the Instructions and Recommendations section.

Очень хочется написать вапрос человеку отвечающему за внедрение некоторых востребованных деталей но не пойму где спасибо за ответ заранее

Сергей, добрый день! По таким вопросам пишите на [email protected]

Прочитал и нифига не понял. О чём статья-то?! Из чего состоит сборный, как его собирать, в чём его ЯВНОЕ преимущество над другими видами – НЕПОНЯТНО!

Виктор, по сути это модернизированный запрессованный сайлентблок. Преимущество в долговечности его работы. Собирать его не нужно, он будет уже собран.

Какую смазку использовать для составных сайлентблоков если в комплекте ее не было???

Действительно, смазка в комплекте не предусмотрена.

Изготавливаемые нами сайлентблоки данного типа в смазке не нуждаются. Если всё-таки хотите применить смазку, то можно использовать любую, т.к. материал маслобензостойкий.

проверяли ли поведение сайлентов на морозе (-30….-55 С)?

Проверяли, работают лучше резиновых.

как это собирать не надо? если вы будете запресовывасть наружую часть в А-рычаг то повредите зелёную часть саленблока т.к. она выступает за наружнюю втулку.

Максим, имелось ввиду что по умолчанию данный сайлентблок идёт в собранном виде. Естественно что перед запрессовкой пыльнички необходимо снять, т.к. с ними установка не возможна.

Купил поставил не Эскейп от Транзата подошли

Поставил в рычаг передней подвески запрессованный сайлент. Авто honda civic ferio 2004 года. Место нахождения г.Томск. Уже год отъездил, нареканий нет. Сайлент цел, нет ни скрипов ни какого-либо дискомфорта.

Сборный*

Фёдор, спасибо за отзыв.

Приятной эксплуатации.

Доброго времени суток.

Подаскажите в автомобиль Toyota Nadia 1998 г.в кузов SXN10 какие сайлентблоки рычага передней подвески рекомендуете ставить, запрессованный или сборный? Заранее спасибо.

Анатолий, лучше поставить сборные.

Добрый день! Купил себе сборный сайлентблок нижнего рычага передний, на хонду cr-v rd7 2002гв. Так как в оригинале присутствуют зоны мягкости, и здесь соответственно тоже. Это для меня было важно. Так как до этого был установлен сайлентблок без зон мягкости !другой фирмы!, который оторвался от внешнего металлического кольца в аккурат по зонам мягкости оригинального сайлентблока не пройдя и 8-ми т\км. Если это здесь кому то интересно, то у меня есть отчет о том неудачном сайлентблоке с фотографиями, повторюсь он не этой фирмы!

Здесь же вид и на ощупь – качественно сделано, все приятно упаковано – никаких рваных упаковок, навязывания конкретной продукции – я выбирал из нескольких сайлентблоков… В общем мне понравился и сам блок и отношение к покупателю 🙂

Антон, спасибо за отзыв.

Приятной эксплуатации!

Здравствуйте, на Toyota Corolla Fielder ZZE122 2001год, ставил фирмы Точка Опоры жёлтые, подвеска стала жёсткой(дубовой, деревянной), чувствую огромный дискомфорт, а как ваши по жёсткости?

Доброго дня! По жесткости можем сказать только относительно сайлентблоков нашей компании, исходя из отзывов и впечатлений наших покупателей. Комфорт дело довольно субъективное и может возникать ощущение, что с полиуретановыми сайлентами подвеска приобретает некоторую жесткость за счет своей большей “собранности” и более правильной работы. При этом все покупатели отмечают, что улучшается управляемость авто. Также впечатления от эксплуатации разнятся в зависимости от марки машины. На ваше авто оптимально подходит 1-16-703. Рекомендуем попробовать 🙂

Добрый день. Вопрос по с/б 15-16-230. В оригинальном с/б внутренняя металлическая втулка расположена не по центру. В вашем с/б, судя по фото, втулка в центре. Или я ошибаюсь?

День добрый! В оригинальном сайлентблоке металлическая втулка расположена по центру. Наш сайлентблок изготавливался по оригинальной запчасти, и в нем втулка также находится по центру.

Добрый день. Вы не правы. У ориг. сайлентблока, арт. 1K0407183P, внутренняя втулка имеет смещение относительно центра примерно на 3-4мм. К тому же на сайлентблоке, оригинальном или аналоге, имеются указательные стрелки для правильной установки в рычаге, что не допускает его установку в рычаг в любом свободном положении. В качестве доказательства можете найти в любом поисковике фото оригинального или неоригинального сайлентблока.

День добрый! Ваш вопрос по сайлентблоку арт. 15-16-230 передали на производство. Они разберутся и, при необходимости, внесут изменения. Спасибо, что обратили наше внимание на данный момент. Хотя, надо отметить, что до сих пор вопросов и проблем по установке данного сайлентблока от наших покупателей не было.

Интересная конструкция!

Скажите, а установка сборного сайлентблока отличается от установки обычного сайлентблока?

Такая же или сборные сайлентблоки устанавливать легче?

Установка сборного полиуретанового сайлентблока принципиально не отличается от установки обычного. Более подробно о процессе замены сайлентблоков можно узнать здесь: Инструкция по установке сборных сайлентблоков

Здравствуйте ! Подскажите пожалуйста какая твёрдость по ШоР у данного сайлентблока ?

День добрый! Больинство сборных сайлентблоков изготавливается с применением полиуретана твердостью 80 ед ШорА. Но модельный ряд сайлентов настолько широк, что нужно смотреть по конкретной модели авто. Заполните пожалуйста Заявка на подбор и наши специалисты помогут подобрать нужные запчасти.

Ставлю себе втулки стабилизатора уже не первый раз на SUZUKI SX4 и SUZUKI JIMNY – выхаживают в два раза больше чем резиновые оригинальные!

В рычаги поставил оба Сайленблока полиуретановые, 12000 км. – полёт нормальный!

Андрей, спасибо за отзыв! Рекомендуем испытать наши полиуретановые крепления off-road. Они очень облегчают и делают удобной перевозку тяжелого инструмента на авто в любую погоду и даже в мороз. Подробнее обзоры о креплениях можно посмотреть здесь: Рейтинги и обзоры креплений из полиуретана

В неразборных сайлентблоках (производства Китай, Корея, Польша и т.д., которые, кстати, довольно быстро выходят со строя) часто происходит отрыв приклеенной внутренней полиуретановой втулки от наружной металлической обоймы. Как решается эта проблема в вашем сборном сайлентблоке? У него ведь тоже полиуретановая втулка приклеена к наружной обойме?

Кстати, я у себя на Ниссан Теана уже ставил передние разборные полиуретановые сайлентблоки на передние рычаги. Они выходили около 30 000 км. Сейчас я снова поставил такие же новые и передние и задние.Но у них немного другая конструкция – у них пыльники не отдельно идут, а отлиты сразу по бокам внутренней полиуретановой втулки, которая запрессовывается в наружную обойму с помощью конусообразной наставник уже после того, как сама обойма запрессована в рычаг. Очень неплохо получилось. Только раньше я их выписывал из Киева, а теперь с доставкой проблема… Да и цена там теперь аховая!

Вот хочу рассмотреть вариант ваших сборных сайлентблоков

Здравствуйте! Наш конструкторский отдел при разработке данных изделий учитывает разнонаправленные нагрузки, которые могут возникать при эксплуатации автомобиля. Если сайлентблок в установочном месте расположен вертикально или наклонно, то лучше, всё-таки, что бы он был к одной из арматур был прикреплён жёстко. В нашем случае он «приварен» к наружной металлической обойме. При применении данной конструкции сайлентблоков, вопросы стойкости адгезии полиуретана с металлом практически не возникают. При горизонтальном расположении взамен сайлентблока можно использовать рессорные втулки с пальцем. Например, для Газели взамен сайлентблоков в рессору мы производим изделие с артикулом 18-20-028.